Over the past several months I have been working on ideas to reduce the assembly time, size and cost of the DÆ stepped attenuator. The image below shows the progress I am making with three versions of the stepped attenuator.

Stepped Attenuators v3.0, v3.1 and v4.0. Each of the attenuators in the figure has 24 total levels.

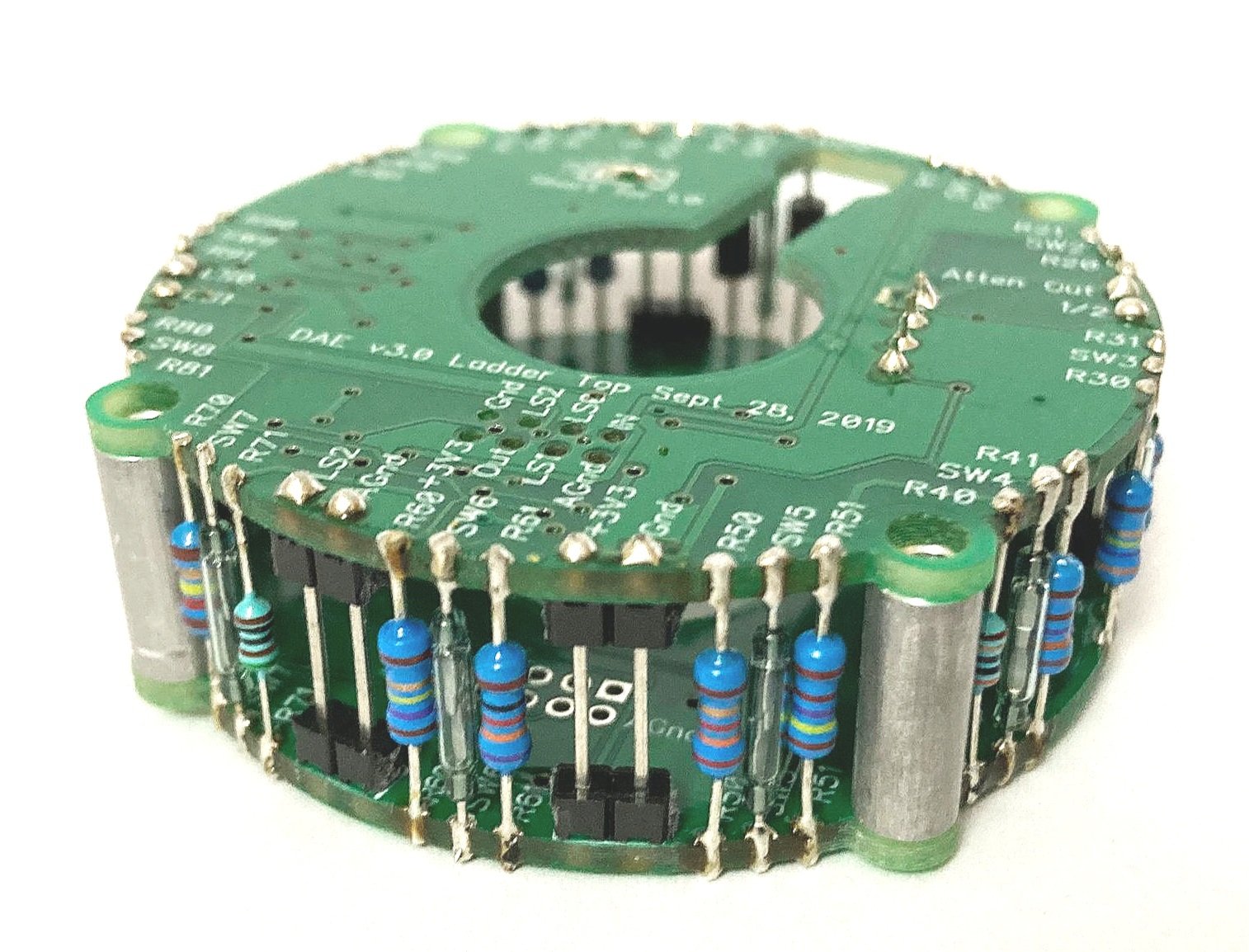

The attenuator on the left is the v3.0 version. This version uses individual through hole resistors around the parameter of a ladder level. A close-up of a v3.0 ladder level is shown in the figure below. There are twelve steps per level so two levels are required to make a 24 step attenuator. I have been listening to this design for at least a year; it works very well and has the benefit of using through hole resistors that toted for good sound amongst some audiophiles.

A v3.0 ladder level. Note the use of through hole resistors and reed switches.

After assembling a few v3.0 attenuators, I started looking for a way to reduce the assembly time. Each of the twelve reed switches and 24 resistors have to be soldered to the level by hand. That makes for a lot of time consuming, expensive in labor and laborious/tedious work.

Enter the v3.1 attenuator which uses the relatively newer technology of a flexible PCB. The figure below is a close-up of a v3.1 attenuator level.

A v3.1 ladder level. Note the use of a flex PCB and surface mount reed switches and MELF resistors.

The flex PCB is laid flat and machine populated with the surface mount reed switches and resistors. See figure below. It is convenient and fast to bent the completed flex PCB around the parameter of the ladder level which considerably reduces the labor required to assembly a ladder level.

A v3.1 ladder level flex PCB laid flat. Note surface mount reed switches and MELF resistors.

The v3.1 ladder level uses surface mount reed switches and MELF resistors. The MELF, or “metal ended little fellows” resistors have a reputation for good sound similar to the through hole resistors but the MELF resistors are surface mount and allowing automated PCB population.

The evolution to surface mount reed switches caused me a few concerns. I was worried that with machine assembly the orientation of each reed switch would be random and it would be difficult to correct a step that didn’t actuate properly. With the hand assembly of a v3.0 level it is possible to install all the reed switches with the same orientation to ensure consistent operation.

To better understand the world of hurt I was getting myself into with the machine assemble of surface mount reed switches, I designed and built the reed switch testing machine described in my March 16, 2022. This machine provided the information I needed to successfully build the flex PCB v3.1 version of the attenuator.

But…

While studying the magnetic sensitivity of reed switches in various directions, I discovered in the literature that a reed switch is also sensitive to a magnet near one of it’s leads.

Aha…

This leads to an interesting opportunity for further reduce in size, cost etc. of the attenuator. Enter the v4.0 attenuator.

Reed switch side of the v4.0 ladder level. Note 24 reed switches per level which equals 24 steps per level.

Resistor side of the v4.0 ladder level. A total of 48 MELF resistors for the 24 steps on a level.

The v4.0 ladder level is made with the more conventional and less expensive rigid PCB and has 24 reed switches on one side and 48 MELF resistors - so there are 24 instead of twelve steps on each level. A considerable increase in packing density. Because the magnet is now positioned around the outside parameter of the ladder level instead of the inside, the diameter of the attenuator is also reduced.

The figure below shows a size comparison of the v3.0, v3.1 and v4.0 ladder levels. The superior packing density of the v4.0 ladder level translates into a reduction in overall size with the v4.0 attenuator being half as long as the v3.0 and v3.1 attenuator. The v4.0 is also ten percent smaller in the other dimensions.

Stepped attenuator. From left to right - v3.0, v3.1 and v4.0. v3.0 and v3.1 have twelve steps per level and v4.0 has 24.

In addition to the reduction in size, the v4.0 attenuator has several other improvements to reduce cost, size etc. without sacrificing quality - of course. Some of the other improvements are:

The knob stepper motor is shorter aiding in the length reduction;

The knob stepper has a built-in encoder. The increases the cost of the motor but helps further reduce length of the attenuator by eliminating the dual shaft and magnet holder of the v3.0 and v3.1 versions;

The control PCB uses an Espressif ESP32 module with dual processors which is more powerful, more popular and less expensive than the previous module. Also smaller, newer, and less expensive, stepper motor driver integrated circuits are used;

The design of the ladder magnet holder was changed making it much smaller. It is now a bent aluminum part instead of a 3D printed part ;

The ladder stepper homing is now done with a stop on the ladder PCB instead of a second magnetic holder and sensor. This again reduced size and cost ;

The v4.0 ladder sections with twice the number of steps per level reduced the number of reed relays required to switch between levels. The level selection reed relays were moved to the rear PCB because there is no space for them on each ladder level.

Of course all these improvements don’t come without a few new headaches. When the attenuator is first powered-up both the knob stepper and ladder stepper are rotated until they hit a stop and are homed. This homing operation is totally silent for the knob stepper because both parts of the homing stop are plastic. Unfortunately, homing the ladder stepper makes a sound that is a close facsimile to a buzzer because the ladder magnetic holder is a small aluminum part. While homing only happens for a short time when the attenuator is first powered-up, it is still annoying considering all the lengths I went to to make the attenuator silent. I am working on solving this problem including using a stepper driver with better electronic end stop detection

I know I haven’t written a blog post in nine months but it not because I haven’t been busy with electronics; it is just that I got busy with too many other projects. What I found is that the supply chain delays caused by COVID meant it would take a month or two instead of a week or two to get custom parts back. I would get bored while waiting and start on another project. Since March 2022 when I submitted my last blog post, I built a Megamote for my mother in-law, a lawn mower lithium battery pack, interface boxes for my SACD player and PVR. None of these are directly the focus of this website but I learnt a lot by building each of them and the knowledge I gained will be useful for upcoming DÆ projects. As an example, I am using the knowledge I gained about lithium battery packs and 18650 cells to design a battery pack for the DÆ products - more on this later.