Your Custom Text Here

The Modular Stepped Attenuator v2.1 is a relay switched stepped attenuator with a difference. It is Quiet!

The relays are vibration isolated and housed in an acrylic vacuum chamber. See video below for an explanation of how a vacuum reduces sound level.

Features:

-Eight up to 64 attenuator steps.

- Left and right channels are fully independent.

- Bluetooth radio for remote control. Search for Dynamic Audio Engineering in the Apple App store for an iOS remote app.

- Stepper motor rotates the volume knob in response to remote control commands Also if right volume knob is rotated, the left volume knob follows and vice versa.

- Four inputs for phono (separate phono pre-amp required), CD, Aux 1 and Aux 2.

The Modular Stepped Attenuator v2.1 is a relay switched stepped attenuator with a difference. It is Quiet!

The relays are vibration isolated and housed in an acrylic vacuum chamber. See video below for an explanation of how a vacuum reduces sound level.

Features:

-Eight up to 64 attenuator steps.

- Left and right channels are fully independent.

- Bluetooth radio for remote control. Search for Dynamic Audio Engineering in the Apple App store for an iOS remote app.

- Stepper motor rotates the volume knob in response to remote control commands Also if right volume knob is rotated, the left volume knob follows and vice versa.

- Four inputs for phono (separate phono pre-amp required), CD, Aux 1 and Aux 2.

Overview

Front

Rear

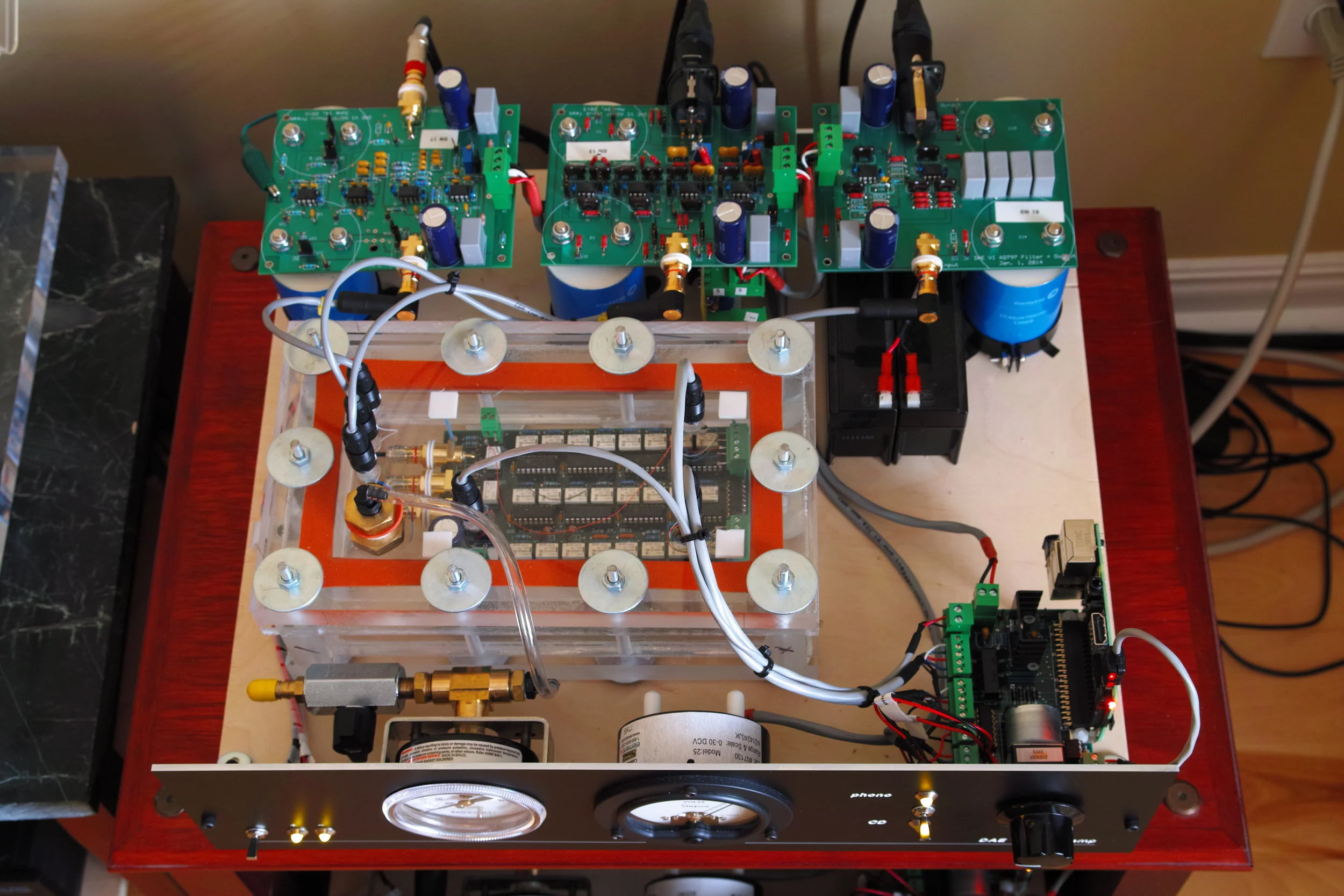

Top

Note cylindrical acrylic vacuum enclosure around relay switched ladder attenuator.

iOS Remote Control

Search for Dynamic Audio Engineering on the Apple App store for iOS remote control app. Sorry no Android app yet but happy to make one if there is sufficient interest.

Bell in a Bell Jar

Demostration of a vacuum chamber reducing the sound level of a bell. A classic physics experiment to prove that sound requires a media (air) to propagate and cannot travel through a vacuum.

First Prototype

A separate relay ladder attenuator printed circuit board in a 19 mm think rectangular vacuum enclosure. It worked but was very difficult, slow and expensive to build. A RaspberryPi on a second printed circuit board controlled the attenuator using a motorized potentiometer.

Second Prototype

This version was in a cylindrical acrylic enclosure but DC motor on didn’t have enough torque to overcome friction of the shaft seals.

Third Prototype aka v2.0

A cylindrical acrylic enclosure around the relay based stepped attenuator. A stepper motor with shaft position measurement works must better. Acrylic enclosure was a little too small to allow an effective seal.